.JPG)

I just collected my leafsprings from NTG and the Jones brothers have done a bloody nice job on them. I was pleasantly surprised by the clamps which had been done as per the drawings and not in the compromise style I had seen on other springs at NTG. I appreciate the trouble Jones' have gone to in order to make the springs look original.

I checked, and the trouble they took with finishing the heads of the central bots was well worth it because, as can be seen in the picture above, they fit nicely into their seatings on the axles.

I am, however, a little anxious about the slack in the inside diameter of the rear spring bush. Carl had said he had difficulty with bushes and I'd imagined he meant with the OD. Looks like I will have to make some kind of shim to take up the slack.

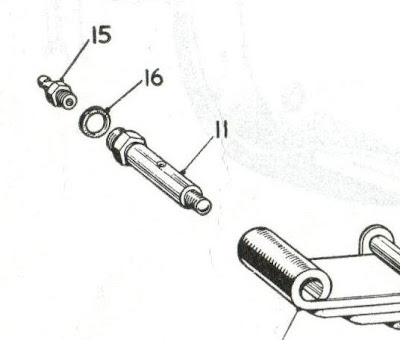

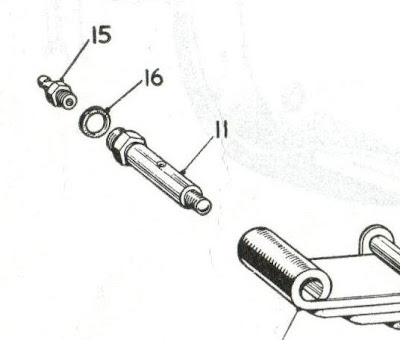

I can't just make the bolt larger....unless I gingerly widen the holes in the castings which hold them on the chassis. This is one to discuss with my mate John. John is currently working on making me up 2 anchors with grease nipples. While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.

While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.

.JPG) John, seen here, has been round today getting me motivated and helping me put the leafsprings on the chassis. We cleaned up some of the anchor bolts, but John machined the one below and is doing some of the simpler ones too.

John, seen here, has been round today getting me motivated and helping me put the leafsprings on the chassis. We cleaned up some of the anchor bolts, but John machined the one below and is doing some of the simpler ones too..JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.

While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.