In July 2005 I borrowed two pieces of kit from the mechanic who services my car (sometimes it is worth being a little cheeky and just asking): a large socket wrench and an ex-RR hydraulic puller set. I was set on taking the wheels apart but because I had removed the axles from the van I had to customise the tools.

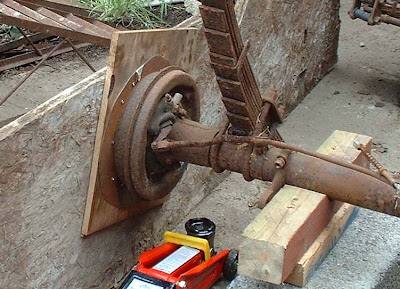

The problem was that the crown nuts at the centres of the wheels were so badly corroded that when I tried to remove them, the entire axle tried to rotate out of my make-shift axle stands when force was applied. So I took a long bit of scrap wood, mounted some metal plate on it with holes cut in it to accommodate the nuts etc and used this as a counter-lever. I found that the socket wrench had to be reinforced at the head to stop it swivelling. It also had to be lengthened to give it extra welly.

.JPG)

.JPG)

Once the wheel centres had been loosened , using the hydraulic puller was a straightforward matter; goodness knows how it could be done without a piece of kit like this.

.JPG)

.JPG)

.JPG)

No comments:

Post a Comment