Monday, 11 August 2008

Where's Tinworm?

Sorry if you haven't received responses to email. tinworm@hotmail.co.uk is the best way to keep in touch but I don't get online as often as usual.

see my flying blog: http://tinworm-wings.blogspot.com/

Normal service will be resumed in September.

Sunday, 13 July 2008

Dash it!

.JPG)

.JPG)

.JPG) Finally, after a month of inactivity on the van and having handed the Magpie blog over to Magpie himself, I got down to the workshop yesterday and removed all the instruments from the dash. I struggled with one pull-push switch, which just would not come out. I got it off today, by brute force, unfortunately; there was really no alternative. I had first established from the manual that it was not an original fitting.

Finally, after a month of inactivity on the van and having handed the Magpie blog over to Magpie himself, I got down to the workshop yesterday and removed all the instruments from the dash. I struggled with one pull-push switch, which just would not come out. I got it off today, by brute force, unfortunately; there was really no alternative. I had first established from the manual that it was not an original fitting.Monday, 16 June 2008

Wythall - 60th Anniversary of the J Type

I came home from Wythall last night buzzing with ideas. The highlight of the day had been seeing Dennis Bradley's inspiring JB tipper truck, sweetly finished in red and grey. It is an absolutely superb bit of work. I took loads of pictures (incl. detail shots) and a few short films....though, idiotically, I hadn't realised that I was taking the latter side-on, as I took them on my new phone! Dur!

I came home from Wythall last night buzzing with ideas. The highlight of the day had been seeing Dennis Bradley's inspiring JB tipper truck, sweetly finished in red and grey. It is an absolutely superb bit of work. I took loads of pictures (incl. detail shots) and a few short films....though, idiotically, I hadn't realised that I was taking the latter side-on, as I took them on my new phone! Dur! The only 101, that I am aware of, was Peter Page's fine looking, crested van. Peter, charming and bow-tied, told me about his trip to St Petersburg at a speed never higher than 40mph!

The only 101, that I am aware of, was Peter Page's fine looking, crested van. Peter, charming and bow-tied, told me about his trip to St Petersburg at a speed never higher than 40mph! Here we see my mate John standing in front of Iain McKenzie's Meccano van. It was good to see it again. I first saw it at his workshop when I went to spend those few days with him, picking up some tricks of the trade and helping him make me some parts. This is one of my favourite J Types and I do hope that if he ever gets the chance to spend some time on her, he does it sympathetically because the tired look suits her. I appreciate that it isn't an original livery, but this is one where concours finish would ruin her authenticity.

Here we see my mate John standing in front of Iain McKenzie's Meccano van. It was good to see it again. I first saw it at his workshop when I went to spend those few days with him, picking up some tricks of the trade and helping him make me some parts. This is one of my favourite J Types and I do hope that if he ever gets the chance to spend some time on her, he does it sympathetically because the tired look suits her. I appreciate that it isn't an original livery, but this is one where concours finish would ruin her authenticity. Actually, I did think that about a number of vans there. Sadly, too many vans are used as business advertising and are therefore done in brand-spankingly new liveries and the slickness just feels wrong. People forget, these were working commercials. So, it was nice to see some of the less flashy vans, brush painted - the more human touch.

And speaking of the human touch, it was great to finally meet people who either got in touch via this blog or who introduced themselves as readers. I was pleased to meet Ken and Jill White and their grown-up kids. The Whites are new to J Types and restoring a planner van. (Incidentally, Ken, did you notice Bjorn's wings? I think they are fibreglass.) Steve and partner Teresa were taking research photos when I bumped into them....they were obviously doing serious under-the-floorboards research, so we quickly realised who we were and introduced ourselves Also I met Alex, whose JB is currently based at Iain McKenzie's, where it is about to go under the knife. Alex was anxious about her condition, but actually his JB has loads of potential, even though its rear cross member collapsed when it was being transported and had to be quickly shored up with a sheet of chipboard as a cross-sectional stiffener. Alex is an interesting chap. He drives freight trains, which seems to be a lucrative business - it is one I considered giving up teaching for last year. We will have to talk more about that, Alex!

On the subject of the humanely done van, it was sad not to see Magpie at the show, though of course I knew in advance that he wouldn't be there. A show doesn't feel complete without OBL. Also, I had hoped that Truman would be there; we had talked of it some time ago. Truman disappeared off the scope a few months ago and I am frankly a bit worried, him being in the Fire Brigade. I have just written by snailmail to see if I can raise him.

A real highlight was the official photographer throwing his toys out of his pram about me going up a bus maintenance gantry to take some photos, while the organisers were setting up an aerial shot of the show. In a squealy voice which belied his gruff, beardy appearance he yelled, "Hey, has anyone told him that only I am allowed up that gantry!" Woooooooooooo! LOL Silly man.Though I know I wasn't exhibiting, I was a bit disappointed not to be invited to join in any of the photos, when all J Typers gathered under the gantry in front of the vans, but Mrs Pitcher stopped me to take my photo at one point, saying she was running a competition for best T-shirt at the show and would be doing a feature. Beth will be pleased!

Saturday, 14 June 2008

Under the clock, carrying a rolled up copy of The Times, wearing a carnation

For those who don't know me but who have said they'll meet me on Sunday, I'll be wearing the bright green shirt my sister had made for me for Christmas this year.......with a J Type on the front. I may even have a yellow satchel type bag with a van on it (stuffed with camera, sandwiches and a notebook). Come and say hi.

For those who don't know me but who have said they'll meet me on Sunday, I'll be wearing the bright green shirt my sister had made for me for Christmas this year.......with a J Type on the front. I may even have a yellow satchel type bag with a van on it (stuffed with camera, sandwiches and a notebook). Come and say hi.Friday, 30 May 2008

Cheers John!

Monday, 19 May 2008

Sunday, 11 May 2008

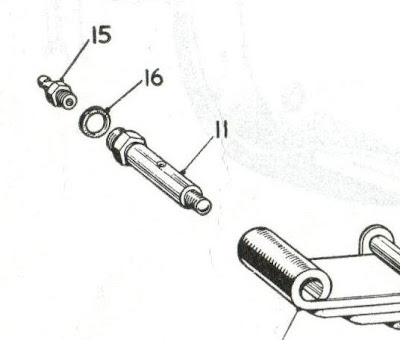

Greased anchor bolt- thank goodness for John

John's a good man! Not only does he have the knowledge, but he is very generous with it. He made this anchor bolt in his precious spare time in school; and goodness knows, we get very little time to ourselves in school these day.

John's a good man! Not only does he have the knowledge, but he is very generous with it. He made this anchor bolt in his precious spare time in school; and goodness knows, we get very little time to ourselves in school these day.I am feeling enormously relieved now that I can just continue on the project in my own time, rather than the depressing rush and pressure I felt under to have a vehicle ready for June. My friend B says that I will enjoy the show more now because I won't be tied to my own van and will be able to get round more and see everyone else's. I will also be saving a few hundred pounds on getting the van there....which can be spent on the restoration.

.

Monday, 5 May 2008

Farting about and problem solving

.JPG)

.JPG)

Today, I rewarded myself for spending several hours marking assessments by spending several more farting around in the workshop - restoration takes quite a bit of farting about, and when not farting, standing round musing. John came round and took away two springs and some shagged anchor bolts, promising to return in a week or so with machined replacements. We have agreed that widening the holes in the mounting castings and widening the front anchor bolts on the rear springs will deal with the bush ID problem.

.JPG)

In the meantime I am refurbishing the rear shackles for the front springs. Today I spent about an hour cleaning up the threads and getting the worst of the rust off. The rubber bushes, surprisingly, weren't too bad. But I shall replace them anyway.

I let myself off the hook today, too. I may not put myself under stress to get a rolling chassis to the June event. It is a lot of expense and stress. I may just go along and enjoy the event and continue the project at a more natural pace......and save the money for the restoration. After all, the work is getting its public airing here.

Friday, 2 May 2008

Leafsprings, by Jones Springs Ltd

.JPG)

.JPG)

While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.

While I was at NTG's, Paul put some rubber bushes on my account. You can see them in the top picture.Saturday, 26 April 2008

adjusted radiator stand

.JPG)

Monday, 21 April 2008

Radiator's done!

.JPG)

.JPG) More about this later because Sheldrake and Wells have done me some photos which are on the way, but for now, am chuffed to bits to have the radiator done. I am told that it is going to be the most efficient it can be; about 30% more than it was. And Andy, who did the work, advised strongly against getting one of those additional fans which can be put on the front to boost it. Apparently this is a two row Q pattern core.

More about this later because Sheldrake and Wells have done me some photos which are on the way, but for now, am chuffed to bits to have the radiator done. I am told that it is going to be the most efficient it can be; about 30% more than it was. And Andy, who did the work, advised strongly against getting one of those additional fans which can be put on the front to boost it. Apparently this is a two row Q pattern core.As you can see, it looks great. Now that it is assembled, it is fractionally too tight for the stand which I made, but some simple modification should take care of it. I have done some measurements, and apparently the bending of the steel caused some loss of distance across the span....amounting to about 4mm in the worst places, so I have just removed a section of the near-side upright and bent an insert to weld in place some millimetres over. It should be fine. I shall finish that tomorrow evening.

Thanks Andy.

.JPG)

.

Sunday, 13 April 2008

"B" channel reproduction with quarterlight surround

.JPG)

.JPG)

.JPG)

Tuesday, 8 April 2008

Spend! Spend! Spend!

I talked to Mark at Sheldrake and Wells yesterday and he showed me a slighly different core, which will be about 30% more efficient than the original. I will do a piece on this specially, but essentially, they remove the top and bottom, clean them out and solder in a brand new core, fit the sides, then paint the entire job. Mark has taken a couple of before shots and will take one in the process of being transformed. I shall let you all have details of the core later.

After work today I rushed over to NTG as they have very kindly agreed to let me send my leafsprings to Jones Ltd using their courier account, which ought to save me some cash - cheaper than Parcelforce etc. It also gives me greater confidence because NTG have a relationship with Jones, who are very highly recommended by them. NTG have done it on account, which is very decent of them.

When these bits are back, I will be making very real progress. By then the axles will be ready to go back on. Am still waiting to hear back from a friend about the size of shocks needed; anyone know?

Friday, 4 April 2008

Progress - The wisdom of a friend

.JPG) I cannot believe how long this job has taken! Incredibly frustrating. I keep telling a supportive girlfriend I am making no progress and how I feel I have wasted my holiday, but she wisely pointed out that if I have been persevering with the job, which goodness knows I have been, then I have been making steady progress on a job which was just always going to take a long time. Some jobs do just take a lot longer than others.

I cannot believe how long this job has taken! Incredibly frustrating. I keep telling a supportive girlfriend I am making no progress and how I feel I have wasted my holiday, but she wisely pointed out that if I have been persevering with the job, which goodness knows I have been, then I have been making steady progress on a job which was just always going to take a long time. Some jobs do just take a lot longer than others. Not sure if Sheldrake and Wells are open on Saturdays, but if not I shall take the rad into them on Monday afternoon, after school, to be recored.

.JPG)

.JPG)

.JPG)

.JPG)

Time-consuming metalwork

.JPG)

Tuesday, 1 April 2008

Carbs and Leafsprings

I also talked to Chris from Brost Forge today about quoting me for leafsprings, which he anticipates being able to do for about £120 per spring, but as he is not online, I have sent him drawings from the manual and a copy of this page showing the dimensions and the Jones Ltd quote, as he may be able to better it.

.JPG)

.JPG)

.JPG)

God, the metalwork seems interminable!

Today, as well as working on the radiator sides, which need loads of adjusting, I trimmed away some rusty sections of windscreen surround and formed and inserted some virgin steel, having removed surface rust from the inner surround. I think I shall MIG drill-spot weld the strip in place. It is larger than what can be seen here. Welding a tab, cut for the purpose, inside will lever it into place....but a tricky bit of welding may be needed along the fringe of fillet....though I am reluctant to do this partly because the material is likely to blow through and secondly because grinding it back afterwards will be tricky in a concave.

I shall then treat the rusty fillet and squeeze POR15 paste into the fillet to cure and strengthen it.

.JPG)

.JPG)

.JPG)

.JPG)